No products in the cart.

Customizable Pouches

Digital or Plate Printed

Made in the USA

Our custom pouches, roll stock, other custom products offer the perfect combination of versatility, sustainability, and quality. Made with eco-friendly materials and in stock for quick delivery, these custom pouches and bags can be tailored to your specific needs, whether you're in the food, beauty or any other industry. The reviews don't like -- our custom pouches are simply the best.

Elevate Your Brand With CarePac's Custom Pouches

CarePac Pouch Bags & Pouches The highest level of customization

Totally Customized Pouches

No fixed sizes, customize every detail of your pouch: size, material, features, print, and configurations. Enterprise level flexible packaging customization available to every company.

CareDesign Service

Need help with art setup on your boxes? Bring what you have and we'll do the rest. The most personalized art support in the industry, comes free with every custom order!

Offering Digital & Plate Printing

No one solution fits all. We don't steer you towards a particular solution. Instead our goal is to meet your brand where it is today and be there for you as you scale and each step of the way.

Custom Pouch, By Industry

From shelf stable and frozen food to pet food, health and wellness and cosmeticscustom pouch packaging is designed to meet the unique requirements of different industries. They are available in various sizes, shapes, and custom materials to suit different product types

and storage conditions.

Food Packaging

FDA approved custom packaging stand up pouches, flat bags, and roll stock offer several benefits for food and beverage products including cost savings and high barrier protection.

Health and Wellness

Custom pouches provide a secure and sterile environment for products, reducing the risk of contamination or damage during transportation and storage.

Pet Food and Treats

Pet food, dog treats and more are almost exclusively sold in flexible barrier packaging, ensure you're competing with th big brands and protecting your product.

CPG Packaging

CPG goes beyond food packaging. Custom flexible packaging pouches offer cost savings for all sorts of CPG products.

Industrial Applications

Prevent bag blowout and bursting with strong durable flexible packaging. Stand up pouches blow hard sided buckets out of the water in price savings and convenience.

CBD & THC Products

CBD and THC require barrier packaging and often need to look towards regulatory compliacne and child resistance, digitally printed CR pouches are a great option.

Industry-Specific Custom Pouches

for Superior Product

Protection and Branding

With the many benefits that custom pouch packaging bags offer, it is no surprise that

they are becoming the packaging solution of choice for many industries.

they are becoming the packaging solution of choice for many industries.

Pouch Customization Options

Flexible Packaging

Carepac Pouch custom bags are a versatile stylish option for carrying small products, and they can be customized with a range of materials, finishes, and printing options. Different custom materials like CareClear, CareSilver, and CareFoil can be used to create pouch bags, each offering it's unique look and feel. Custom finishes such as waterproofing or adding zippers can be added to enhance the functionality of the bags. Printing options like screen printing, heat transfer, or embroidery can be used to personalize the bags with logos, graphics, or text. With the ability to customize materials, finishes, and printing options, custom pouch bags offer a unique way to showcase custom branding or create a custom accessory for personal use.

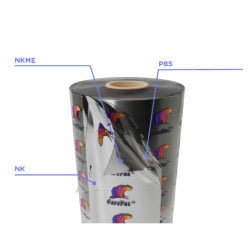

Pouch Printing

With both digital and plate printing options, we can scale as you grow and passing savings on to you. We also offer all the popular stand up bag finishes.

Material Selection

We offer a greater selection of custom material options than our competitors, from foils to compostable with great compliance support: PFAS, 23 CRF 73s, prop 65, R.E.A.C.H, RoAH, and more.

Bag Configurations

Our wide selection of pouch configurations gives you the most control over your packaging ensuring that your pouch fits your product like a glove. Stand Up Pouches, Flat Bottom Bags, view windows, and many more.

Zipper and Feature Options

Re-closer options abound with standard press to close zippers, pull-tab zippers, and tin-ties. CarePac also offers other optional bag features like degassing valve, hang tags, view windows, and tear notches.

CarePac Packaging Partners

The process of creating custom packaging for products is a hassle-free manner using carepac. Custom packaging allows business to stand out and promote their brand while keeping their products safe during shipping and handling. The process involves designing and selecting packaging materials, customizing the packaging to meet specific needs, and producing the packaging in bulk. With the help of modern technology, custom packaging can now be created easily and affordably, allowing business of all sizes to help their products stand out from the crowd.

Eco Friendly Stand Up Bag

Design & Customization

Custom eco-friendly pouch bags are a great way to reduce waste and minimize your carbon footprint. Made from sustainable and biodegradable materials, these bags are a stylish and practical alternative to traditional pouch bags. They are not only durable and reusable but also free of harmful chemicals and toxins that can harm the environment. Additionally, they come in a range of sizes and designs, perfect for various purposes. By choosing eco-friendly pouch bags, you can make a positive impact on the planet and set an example for others to follow.

Recyclable Bags

With our new and improved BOPE based recyclable films you can have a fully recyclable bag in any custom configuration you need including box bottom bags.

PCR Packaging

PCR film is a great transitional material from transitional non-recyclable films to fully recyclable. PCR content up to 80% is available. Most pouches can be made with PCR.

Compostable Bags

CarePac offers both commercially and ambient compostable material options. Compostable films are constantly improving.

Biodegradable Bags

Biodegradable bags are an important development in custom flexible packaging. With our Biodegradable film solution you can define your company's environmental impact.

Family Owned

Carepac is a family owned and operated company based in Southern California. CarePac focuses exclusively on custom flexible barrier packaging such as bags and pouches. CarePac offers deeper knowledge, better product selection and higher quality service than our competitors. When you work with CarePac, you'll work with a real person that's transparent and business focused.

CarePac Express

Fast Custom Printed Pouches From As Few As 100 Bags.

Prototpying, Trade shows, just want to make sure it's all perfect? Consider Carepac Express our fast super short run offering. of set size digitally printed bags. CarePac Express is a great way for start-ups and those looking to prototype to get into printed packaging. These pouches come with a printable area on the front or back. The printable area can be used to add branding, product information, or even QR codes. CarePac Express pouches are offered in common materials like Silver, White, and Clear each suitable for different applications. These pouches are easy to use and can be customized quickly making them ideal for small businesses, startups, or even home-based businesses.

Connect with CarePac Pouch Bag Experts for

Customized and Stylish Packaging

Totally Custom Packaging Made Easy

Step 1:

Get a Quick Quote

Step 2:

Decide On Details

Step 3:

CareDesign Total Support

Step 4:

Bag Making

Step 5:

Enjoy Your New Bags!

Step 1: Get A Quick Quote

Full Customization of every detail? You heard it. With CarePac's custom pouches we don't limit you to set sizes, or a couple of materials. You have access to the full selection of configurations, materials, finishes, features, and more.

We don't need all the details right now to get you a quick price, so get this ball rolling and get a quick quote today.

Step 1: Instant Online Quote

Every custom bag we print goes through a very specific set of steps, from choosing your bag size, material and configurations, to proofing, to final delivery. With more than 10 years experience, we will walk you through every step of the process to ensure your bag will fly off the shelf.

We make it easy for you to get an instant online estimate using our bag calculator. Choose how many bags you want, how soon you need them, what type of bag you want and what features you want. Get a free instant price quote today!

Or feel free to give us a call. We’re happy to help.

Step 2: Sizing and Configuration

Pick the exact right size custom printed pouches for your product. All custom printed pouches that we sell can be custom sized, with custom die-cut windows, or other unique configurations. Generally if it is possible with a flexible material then we can supply your custom printed pouches, not a problem.

Because printing occurs before the bag or pouch is made, (we print the roll stock), sizing and configuration is totally customizable to your specifications. You can customize the size of your package to exactly what you need.

Step 3: Master Art Proofs

You don’t have to bring press ready art. There are many technical considerations when printing barrier films, and we do all that work for you. We’ll take your original art files and set them up for printing to ensure you get the best quality printing, and develop digital art proofs that you can revise. We focus on providing custom printed pouches and barrier packaging that meets your budget.

Step 4: Material Is Printed

We offer Digital, Plate, and cylinder printing options for making your custom printed pouches. So once the material rolls are cut, treated, they are then printed, and finally any lamination is applied (matte, gloss etc).

Step 5: The Bags Are Made!

The printed material is then made into your bag.We offer a selection of finishing laminations, and varnishes for your custom printed pouches.

Compliant Packaging

Compliant packaging is so important these days. With stricter requirements from every distribution channel let alone the state and federal government. Don't be left hanging with dodgy compliance. CarePac has you covered.

You've Seen Our Printed Bags & Products

FAQ's

Our FAQ section for custom printed standup pouches and bags offers valuable information for businesses looking to create custom packaging solutions. It covers common questions related to design, making materials, printing, and shipping, providing clarity on the customization process.

Why is a custom size pouch important ?

Custom size perfect for stand-up pouches refers to the ability to create pouches that are tailored to the exact specifications and requirements of the customer. These pouches can be made to any size and shape, ensuring they fit the product perfectly and provide maximum protection and visibility. Custom size stand up pouches are ideal for businesses that need packaging that is unique and tailored to their specific needs. They can be used for a wide range of products, including food items, pet food, cosmetics, and pharmaceuticals, among others. Custom size stand-up pouches can also be printed with high quality graphics, logos, and product information to help brands showcase their products effectively and attractively, overall, custom size stand-up pouches offer a versatile and customizable packaging solutions for businesses looking to stand out in a competitive market.

What is the process for a custom stand-up package?

The process for creating a custom stand-up packages involves several steps. first you provide us with your logo and graphics that you want on the pouch and decide on the specifications and requirements for the pouch including the size, shape, material and design. The supplier then creates a prototype or sample of the pouch based on the customer's specifications. The customer can review the sample and make any necessary changes or modifications. One the design is approved, the supplier begins the production process, which involves printing the design onto the packaging material, cutting and sealing the pouch, and adding any additional features such a zippers or tear notches, quality control checks are conducted throughout the manufacturing process to ensure that the pouch meets the customers specifications and standards. Finally the custom stand-up pouches are shipped to the customer for use in packaging their products.

What are custom printed stand-up pouches?

Custom printed stand-up pouches are a type of flexible packaging that is designed to stand up right on store shelves, creating an attractive display for the product inside. These pouches are made from multiple layers of barrier film that protect the contents from moisture, oxygen, and other external factors that can affect the product's freshness and shelf life. The pouches can be customized with various printing options, to help brands showcase their products effectively. Custom printed stand-up pouches come in different sizes, shapes, and finishes, making them suitable for a wide range of products, including snacks, pet food, coffee , and other food and non-food items. They are a popular choice for brands looking to differentiate their products from the competition and attract consumers attention. You can add hang tags or a view window so your customer can view inside.

What material are used to make custom stand-up pouches?

Custom stand-up pouches can be made from a variety of materials, including plastic, paper, foil, and biodegradable options like compostable films

Can custom stand-up pouches be resealed?

Yes, many custom stand-up pouches come with resealable zipper or other closure options, allowing the consumer to open and close the pouch multiple times.

What is the minimum order quantity for stand-up pouches?

The minimum order quantity for custom stand-up pouches varies depending on the supplier and the size and design of the pouch. However, some suppliers offer as.

Let's Get Started!

Whether this is your first bag or your millionth, our expert care team is here

to help you stand out from the crowd.