No products in the cart.

Custom Cannabis Packaging &

Packaging for Marijuana

Custom Mylar Pouches

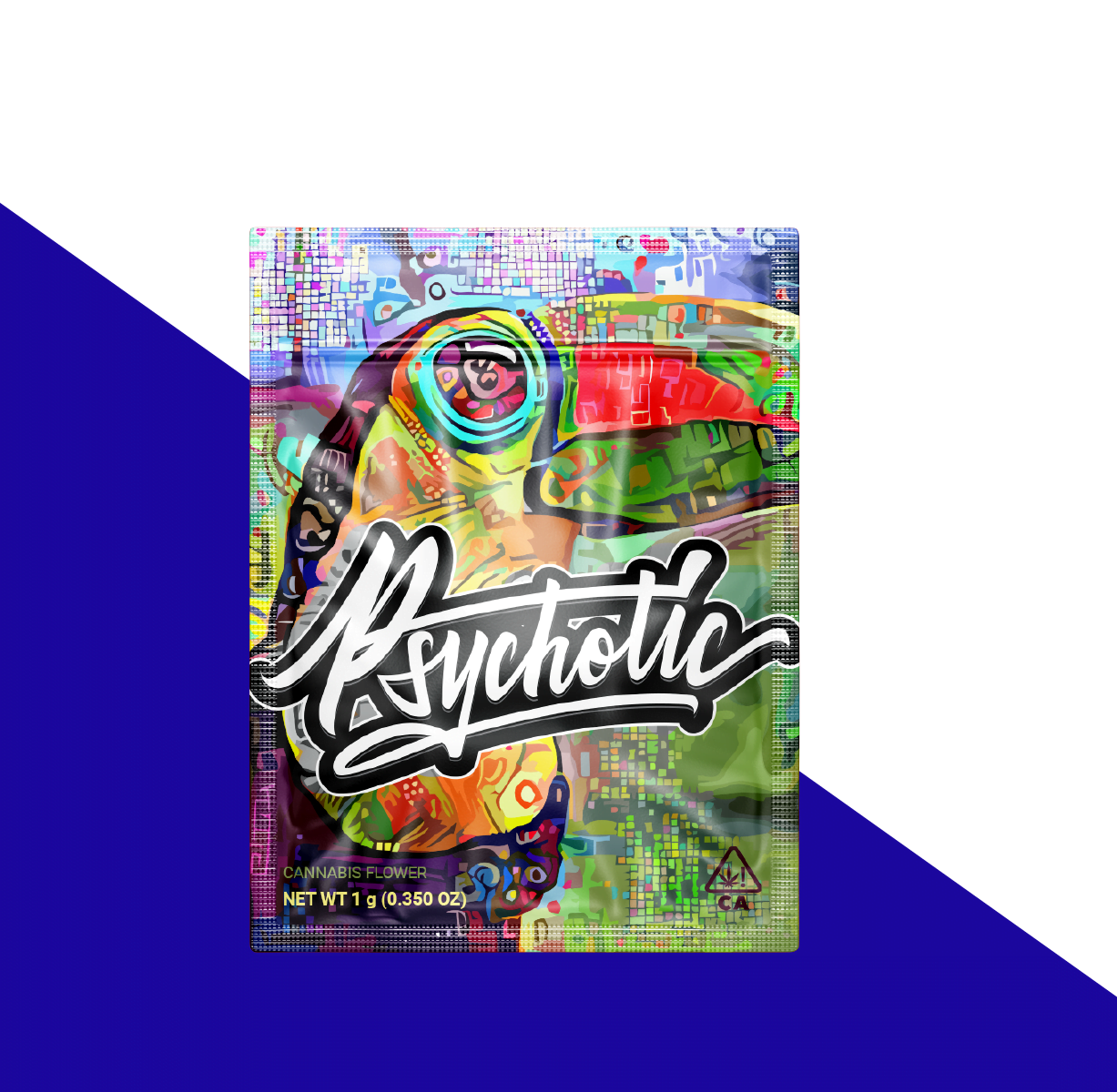

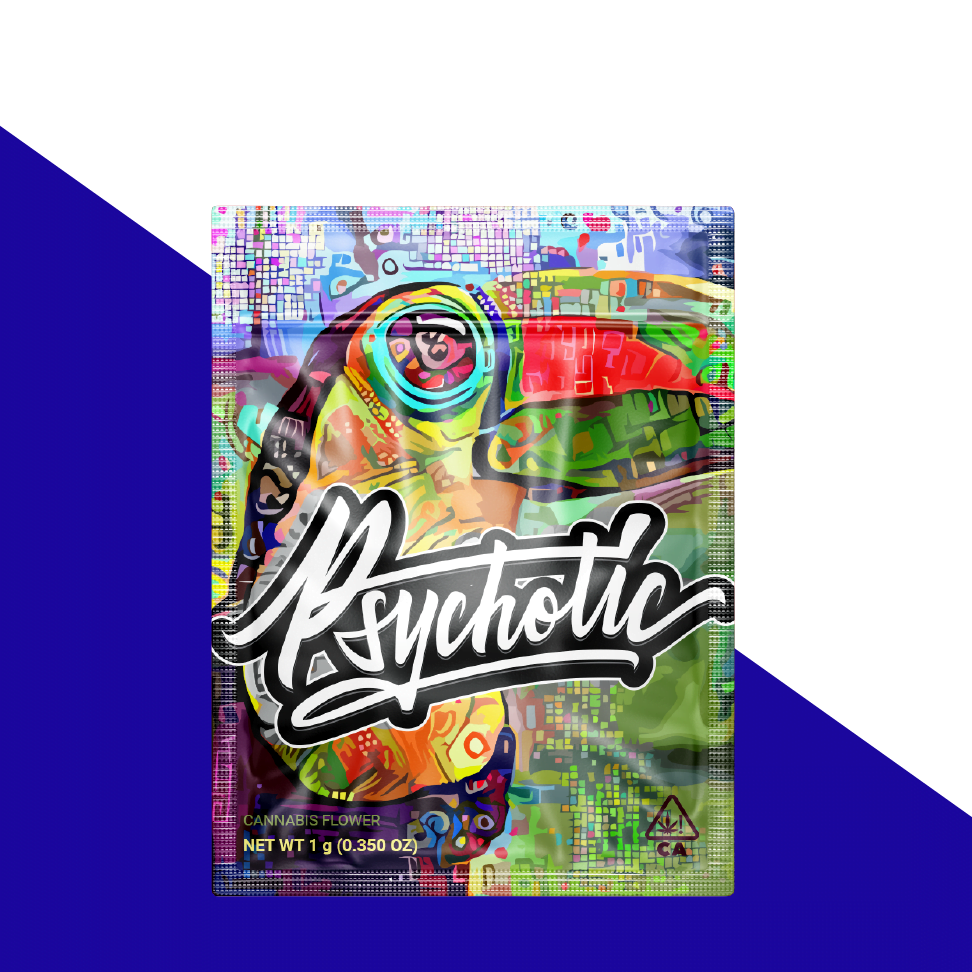

Many cannabis companies are moving away from the older and more expensive packaging solutions such as bottles and boxes and switching to custom cannabis packaging. Mylar bags are used for anything you can think of: cannabis, edibles, jerky, coffee, cones, cookies, liquids, herbs and provide extended freshness and protection for flower and edibles.

Customize size and printing your own mylar bags is the best way to differentiate yourself from your competition.

Cannabis Packaging

Combining total customization with the highest quality printing helps differentiate your brand from the competition. The artwork on your Mylar bag goes a long way in helping customers make their buying decision, both online and in person. Marijuana packaging has confusing regulations that can vary from state to state, here at CarePac, we understand these requirements and have the capable solutions to ensure that your products are within jurisdictional compliance.

Custom Smell Proof Pouches

Stand up pouches are manufactured with a bottom gusset which, when deployed, allows the pouch to stand up on the shelf in a store, instead of laying down like flat pouches. Commonly referred to as SUPs, this gusseted package have more space than a 3-seal with the same outer dimensions.

Features of Cannabis Packaging

Our smell proof Mylar bags are perfect for cannabis companies of all shapes and sizes. Our packaging offers the highest level of odor containment, ensuring that no air will escape from your product. From cones vaporizers cartridge, we have the packaging for you.

And no air escape = no smell escape. CarePac makes and sells a wide variety of premium Mylar smell proof bags wholesale that can meet various compliance packaging requirements. They're tamper and resistant to children, and won't emit the scent of cannabis. Plus, they can be fully customized to match the branding of your company.

Comply with your state laws

Legal requirments are often changing and each state has their own take on packaging, labeling, and dosing. We sell custom packaging to customers from almost every state imaginable, even Puerto Rico! CarePac even sells outside the USA to Canada, Europe, and too! So we have seen it all and can help you develop your design in the most compliant way.

The Stand Up PouchShop By Size | By Use

Stand up pouches are manufactured with a bottom gusset which, when deployed, allows the pouch to stand up on the shelf in a store, instead of laying down like flat pouches. Commonly referred to as SUPs, this gusseted package have more space than a 3-seal with the same outer dimensions.

Easy Loading Tamper Resistant Pouches & Tamper Evident Heat Shrink Sleeves for Jars

Tamper Evidence is critical to assuring that your customer knows if a bag or their vaporizer cartridges or vaporizer batteries have been opened prior to their first use. Since it shows clear signs of tampering, it prevents unauthorized tampering with a bag's contents. Tamper Evidence requires that the end consumer physically alter the packaging in such a way that it is plainly evident that the bag has been opened. For clear plastic bags this is accomplished using a tear notch and heat seal. The consumer uses the tear notch to physically tear away the top of the bag. From that moment forward anyone can plainly see the bag has been opened. These flat poly bags are great for storing cash, card, accessories, and other high security items.

Finish Options

We offer all the popular pouch finish options (glossy, matte, soft touch) but we don't stop there. CarePac offers an expanded selection of finishes beyond the normal ones. Spot UV, Holographic, and metalized finishes are all available options for you here at CarePAc. For a full breakdown of the finish options offered through CarePac, please visit our finishes page for more information.

Spot UV

Spot UV finish creates a interesting combination of matte and gloss so that logos pop out from the design.

Metalized Finish

Metalized finishes and effects provide a unique look to your pouch. Metalized effects stand out from the competition.

Soft Touch Finish

Soft Touch haptic finishes are a matte finish that also provides a soft smooth hand feel.

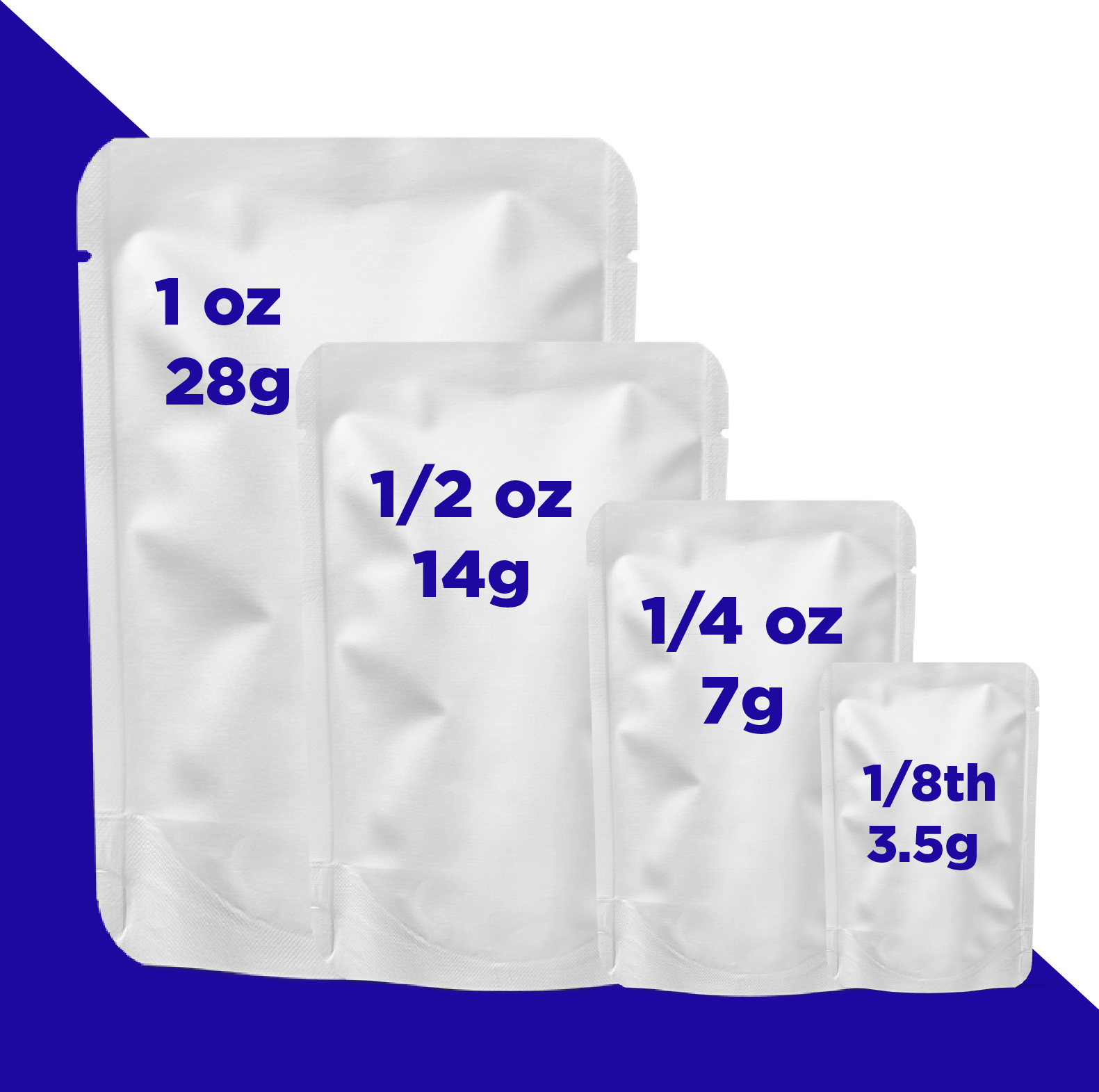

Custom Sizing Is An Opportunity to Create Unique Baggie

This is the area where rotogravure printing really shines! Roto printing is compatible with all available finish and labeling options, and is even compatible with 2+ finish options on one single pouch. CarePac has a variety of finishes to choose from, including soft touch, holographic, and metalization. For a full breakdown of the finish options offered through CarePac, please visit our finishes page for more information.

Packaging Size

Exit Bags

Pound Bags

Customized for Edibles and Concentrates

Looking for Cannabis Packaging for Specific Locations

Cannabis Packaging FAQs

Your packaging is one of the most important parts of your company. Whether you’re focusing on the look and feel of your brand, the freshness of your cartridge filling and other products or both – we’ll answer your questions! If you’re still not sure what kind of bag you need, reach out to our team and we’ll answer your important questions. If you don’t know what kind of design you are looking for, we can get you hooked up with a graphics designer to help bring your brand labeling onto the pouch.

Q: Do you offer wholesale pricing when buying cannabis bags in bulk?

Yes, with CarePac you can save even more with our everyday, wholesale pricing available on both our logoed bags, custom bags or our stock bags. They're much more affordable than jars, tins, or bottles. Whether you are packaging flower, pre-rolls, or edibles.

Q: Do you offer custom sized weed baggies?

Looking for a more specific pouch size for your packaging needs? We have got you covered. We have come to understand that sometimes our clients are looking for something more specific. A specific size or configuration – that is why we offer customized bags to meet these needs. We make it fast and easy. We make them so you can even use your artwork and designs. Whether you need food-grade pouches, marijuana packaging, or tamper-evident packaging, we’ve got you covered. We even offer smell-proof, child-resistant Mylar bags that are perfect for use with marijuana packaging.

Q: Can I print my own design on my custom cannabis packaging?

Depending on your needs and preference, we offer printing both digitally and with the use of plates. While digitally printed bags come with several advantages, we sometimes advise clients to opt for plate printing depending on their needs. Majorly because plates offer the lowest per-bag price points. However, digital prints offer a more robust color count and are its best for short run usage. Whichever the case, we always have a support staff to walk you through the production process and help you identify which printing is best for your project.

Q: Do you make child resistant weed bags?

Yes, we do offer child resistant zipper that will fit for the marijuana weed bags you need. Being cautious with the product you are selling, CarePac has lots of options for cannabis or marijuana to properly be sealed in a pouch bags.

Q: Can you put a child resistant cannabis bag in a refrigerator?

No, avoid placing marijuana bag in a refrigerator. The temperature and humidity fluctuations are too much for cannabis or marijuana if you store it in the fridge or freezer. Freezing the bud makes it brittle and the THC-rich trichomes will break off, leaving you with weak weed.

Q: What if I need help designing my weed packaging?

You don’t have to bring press-ready art. There are many technical considerations when printing barrier films, and we do all that work for you. We’ll take your original art files and set them up for printing to ensure you get the best quality printing and develop digital art proofs that you can revise. We focus on providing printed pouches and barrier packaging that meets your budget, and can help you get started with labeling and design.

Q: What is the standard lead time on a custom printed weed bags?

In our industry, contrary to what you might think, ten-week Lead time is not uncommon. We offer the best lead-time options on all our quotes compared to other brands. With lead time options as low as 15 working days with our digital express service.

Q: How much does custom printed cannabis bags cost?

Get a quick free quote and pricing sheet by email, using our free online quick quote form to get a cost for your bags.

Q: How low is the Minimum Quantity Order for printed marijuana weed bags?

Printed Weed Bags we offer as low as 500 or 1,000 for digital and as low as 5,000 for plate printing. High quality printing services and materials in a low price.

Q: Are your cannabis bags smell proof?

Yes, high barrier flexible packging can be smell proof bags from stock bags to marijuana bags. We make it sure that it feature smell proof bags especially with marijuana packaging. When you’ve got weed on the go, it’s easy for the telltale skunk smell to give you away. Making marijuana packaging a smell-proof bags to transport your weed discreetly helps to conceal the smell of your weeds.

Q: Is it safe to add a clear window on cannabis packaging?

Adding a quick view window is a good idea but it would cause the contents to be exposed to light. Exposure to light is the biggest culprit when it comes to aging marijuana. According to study of published in the journal Pharmacy and Pharmacology, light is the single largest contributor to loss and deterioration of cannabinoids and suggested that “carefully prepared herbal or resin cannabis or extracts are reasonably stable for 1 to 2 years if stored in the dark at room temperature.”