No products in the cart.

Eco Friendly Packaging

The Best Eco-Friendly Packaging

From Compostable packaging to recyclable packaging. CarePac has cutting edge options for compostable and biodegrable plastic bags.

What Is Eco-Friendly Packaging?

Eco-Friendly Packaging is barrier packaging that comes in several forms: recyclable, sustainable, biodegradable, or compostable.

Companies today are searching for a more environmentally friendly approach to reducing their ecological footprint. One way to do that is to use eco-friendly packaging. But for many companies, making the switch can be a daunting process.

Laminated plastic barrier films are among the most popular and important materials utilized in the modern world. These materials can enhance shelf life, protect the products for the elements, and reduce weight in transport.

But, these same amazing properties make them difficult or near impossible to recycle. Through the use of specific recycle ready materials, your bags and pouches can be recyclable.

One of the big challenges is that eco-friendly materials do not always perform the same as the more traditional barrier materials made of plastics, aluminum, and other synthetic materials. But in the long run a switch to sustainable packaging will make your company far more appealing to consumers. Carepac offers several packaging options which can meet your unique requirements.

Why Use Environmentally Friendly Packaging?

Eco-Friendly Packaging, also known as sustainable or Green Packaging, is becoming the focus of government regulation and consumer preference. Green packaging can greatly reduce your impact on the environment. Doing so may help you attract more customers by demonstrating your commitment to environmental responsibility.

No matter what industry you are in, eco-friendly packages are versatile enough to suit most application.

But not all products are a good fit for eco-friendly packaging. While the technology continues to improve, the limitations of these materials should not be underestimated for certain applications.

Questions to ask before switching to Eco-Friendly Packaging:

• Will there be a similar shelf life?

• Will you have adequate protection for your product?

Three Types of Eco-Friendly Packaging

Recyclable, Compostable and Biodegradable packaging are sometimes mistakenly used interchangeably when describing a bag's materials. However, there are significant differences between them, including: selecting the right application for the right purpose, and determining how the end user will dispose of the packaging.

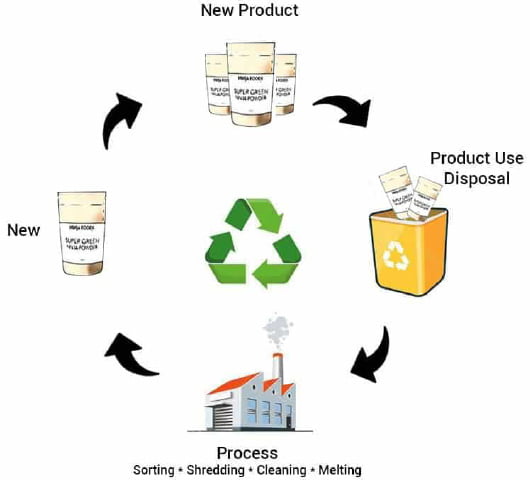

What is Recyclable Packaging?

Recyclable materials can be reprocessed into new items. Following the “reduce, reuse, recycle,” waste hierarchy this avoids resources being lost into the landfill or incinerator. The package can be reused as a similar item (for example glass bottles into glass bottles) or into a lower grade material (for example composing paper into toilet rolls).

Applications for Custom Recyclable Bags

When recyclable plastic bags could be a good fit:

Pasta and Dried Goods

Light Weight Powdered Products

Nuts and Seeds

Candy, Chips, Cracker Packaging

When recyclable plastic bags are NOT a good fit:

High Barrier Applications

High Strength Applications

Pharmaceutical Packaging and Baby Food

Spout Pouches

Custom Printed Recyclable Bags

Impress your customers and help the environment with recyclable plastic bags and stand up pouches.

We sell recycle ready in the following configurations:

• Stand Up Pouches

• 3 Seal Bags

• 2-Seal Fold over bottoms

• Fin Seal bags

Biaxally Oriented BOPE/PE

Mono-plastic lamination of BOPE and PE

Biaxially oriented PE laminated to LLDPE creates a heat sealable film which can be converted into Stand Up Pouches, Lay Flat bags and other similar bag configurations.

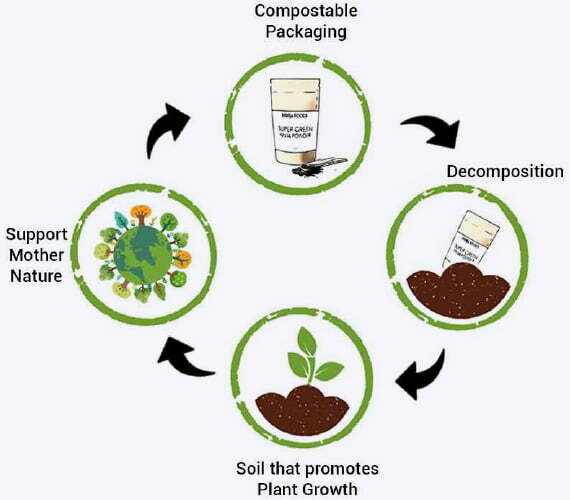

What is Compostable Packaging?

Compostable materials require unique conditions to break down and may not compost in landfill. Many cities still lack the infrastructure to gather and move compostable packaging to composting facilities. When specific composting collections are not available locally the best option to compost on site is what’s called Ambient Compostable.

Compostable Plastic Bags – A Subset of

Compostable Bags

Compostable Plastic bags are a new generation of plastics which are biodegradable through composting.

Compostable Plastic Bags are derived from renewable raw materials (e.g. corn, potato, sugar cane, cellulose, soy protein, lactic corrosive, etc.). The bio-plastics are not hazardous to produce and are intended to break down into carbon dioxide, water, biomass (soil) when composted. There are some compostable plastics that are not derived from renewable materials, but instead made using petroleum or made by bacteria through a procedure of microbial maturation.

When recyclable plastic bags are NOT a good fit:

Compostable bio-plastics will break down in soil unlike traditional bags which last for up to 500 hundred years or more.

Applications for Compostable Bags

Compostable plastic bags could be a good fit:

Pasta and Dried Goods

Tea and Coffee

Nuts and Seeds

Candy, Chips, Cracker Packaging

Popcorn, Snacks, Spices Salt, Sugar, Flour, Pet Food, Bird Seed, Cannabis, Supplements, Milk Powder, Protein Powder, Tea & Coffee, And More…

Compostable plastic bags are NOT a good fit:

High Barrier Application like freeze dried fruit

High Strength Applications

Pharmaceutical Packaging and Baby Food

Liquid Spout Pouches

Products requiring vey high strength or barrier (moisture and oxygen) or extended shelf life are not going to be ideal candidates (yet) for compostable plastics)

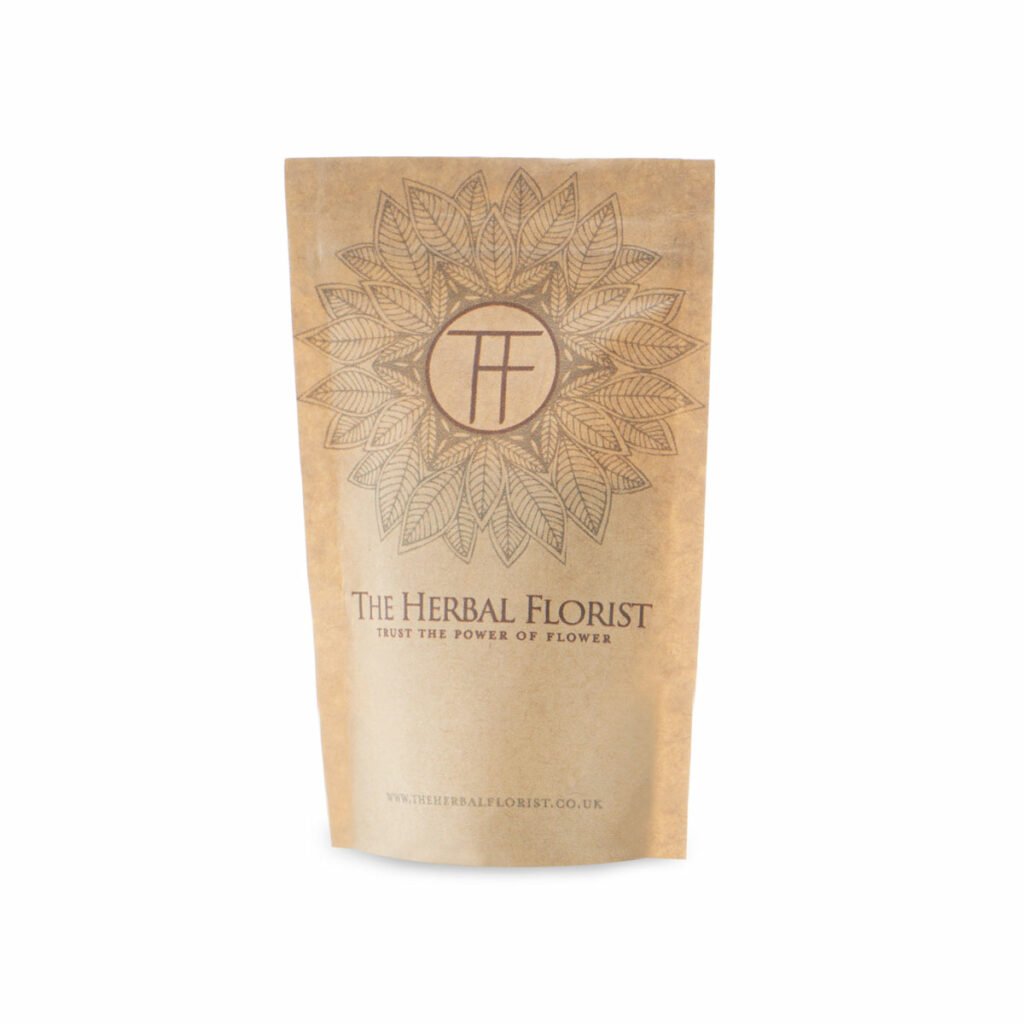

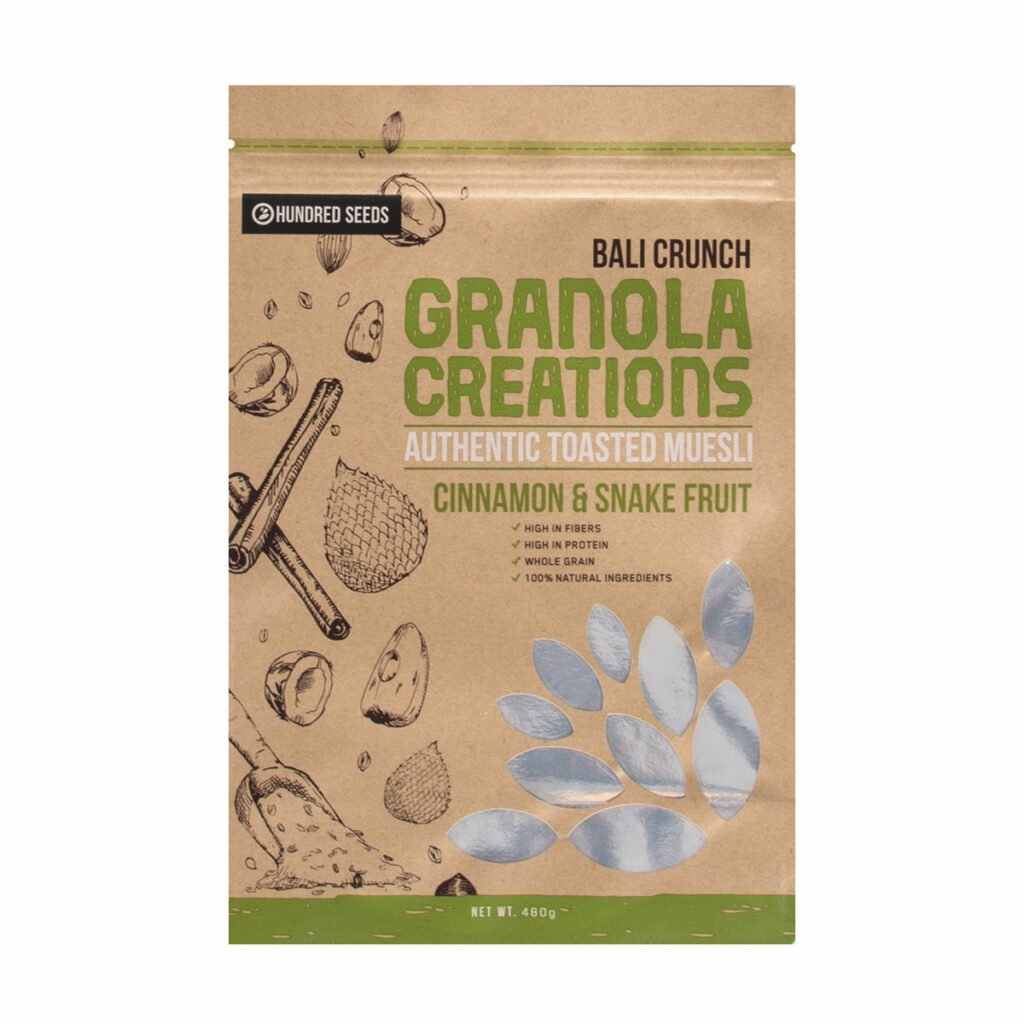

Custom Printed Compostable Packaging

Our compostable packaging options include a selection of materials that are industrially and/or ambient (home) compostable. Many of our 5000 series of materials are compostable, yet also provide the barrier you need to protect your product and provide shelf stability.

We have FCN approved compostable packaging solutions that will compost under ambient conditions and are made of renewable resources. These materials are the future of barrier technology.

We are always partnering with film makers to offer our customers the newest innovations in compostable barriers, made of bio-plastics such as Sugarcane, corn, and casava.

• Environmentally Friendly and Green products

• Both Recyclable and ambient compostable are both available.

• Enhanced barriers and multiple thickness options.

Custom Printed Compostable Bags

Most common pouch configurations are compatiable with these materials, including:

• 3 Side Seal

• Tamper Evident

• Stand Up Pouch

• Square Bottom Pouch

• Tubing

• Non-Printed Custom

Compostable Packaging Material Options

To provide customers with the most advanced offerings in compostable products we work with film suppliers / laminators with a wide selection of compostable and biodegradable materials. Compostable packaging options are evolving and always changing, and we plan to add more material options in the future.

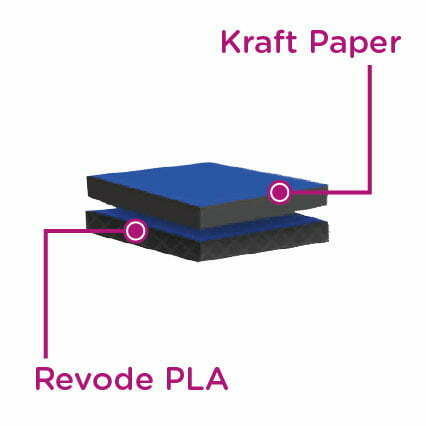

CareCompost KP

BioCareKraft and BioClear are compostable packaging materials great for most dry and semi-dry food items, including sustainable coffee bags. Both materials provide barrier protection and can be composted. We have several thickness options to increase visual appeal and barrier.

• Exceptional Price points and order sizes

• Multiple thicknesses

• Compatible with most pouch configuration

• Printable

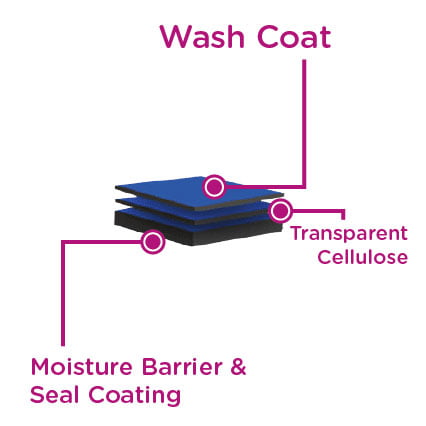

CareCompost NPT

NatureFlex is a amazing compostable, heat sealable and transparent material. Made from renewable resources, with excellent transparency and high gloss levels. This compostable pouch complies with CFR73 food contact regulations and meets both US and EU standards for food contact. This compostable pouch film meets EN13432 and ASTMD6400 compostability standards.

• Excellent moisture barrier

• Heat Sealable

• Transparent

• Anaerobic diestable

• Resistant to oil and grease

BioPBS (PTT / Mitsubishi Chemicals)

A unique PBS based material. BioPBS is made from Sugarcane, Cassava, and corn, and readily decomposes and biodegrades into biomass, water and co2 at ambient temperature conditions in open air landfills and requires no specialized compositing facilities.

• Food Contact Approved

• Approved for high temperature applications up to 100C

• BioPBS is often used as a sealant layer and combined with a cellulose or Saran.

• High Minimum order quantities due to availability.

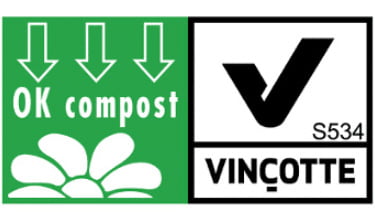

Compostable Packaging Certifications

There are multiple levels of certifications, both by industry associations as well as governmental organizations. Generally, there are two types of compostable packaging:

1) Industrially compostable materials, which can be composted in an industrial composter, and

2) Home compostable (ambient) which can compost under standard home composting environments.

The process of composting requires a combination of temperature, microbial life, water, oxygen, and other factors. Several labeling schema have been developed to identify the compostable and disposal characteristics of compostable packaging materials. DIN Certco and Vinçotte being the two many organizations pushing these labeling standards.

Bio-based carbon claim certifications ASTM D6866

D6866 is the ASTM certification basis for the USDA and Vincotte labeling standards for bio-based content claims. Additionally Bio-based plastics are plastics that are derived not from Petrochemicals. They can be both partly bio-based, or fully bio-based.

Additional Certifications are available

FDA 21 CFR 73

CFR Condition B

RoHS

SR 817-023-021

EU 10/2011

REACH

CA Toxins in Packaging / Prop 65

BPA/TSE/BSE

Consortia SLT

Kosher

CONIG

Disclaimer

Information presented has been collected from various sources including our film suppliers. We assume to the best of our knowledge that the information presented is will provide a accurate representation of the available data and present situation. Film data an compliance information was provided by our film suppliers and should be considered average values, and are given without any obligation on our part, and we are not responsible for their accuracy.

Bio-based and biodegradable plastics are a large family of materials with widely varying properties. As with all plastics, whether a particular material is suitable for your application depends entirely on the specific facts of your application, and must be determined by you.

Biodegradable materials will break down naturally, yet there’s no time span. A fork that is biodegradable could be covered for a considerable length of time before it starts to break down. A biodegradable material can be characterized as a material which can be decayed by bacteria or other natural organisms and not be adding to pollution in environment.

Custom Printed Biodegradable & Sustainable Bag Packaging

Looking to reduce your company’s footprint with more eco friendly packaging?

We offer several biodegradable options for developing your custom packaging! There is a lot of hype about Biodegradable packaging, and many companies are trying to sell the sizzle, but many products are not as biodegradable as you might believe.

We believe our customers should have the most knowledge possible when making purchasing decision, so we’ll cover some of the basics, and our available options!

In our fast-changing environment and throw-away culture, there is a significant need to make materials which can be recycled or that are biodegradable.

Biodegradable packaging is one of the new and very exciting developments in flexible barrier packaging.

Biodegradable Packaging is Plant-Based & Compostable

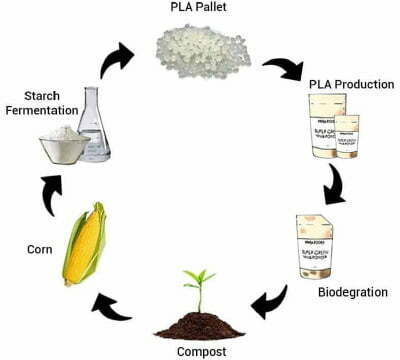

One of the predominate base materials for this is Polylactic Acid (PLA), which is an eco-friendly material made of sugar cane, starch and corn. PLA is primarily created using renewable or green sources. Biodegradable packaging is not recyclable. This might seem strange, but the goal of biodegrdable packaging is different than recycable packaging.

Biodegradable PLA production is a popular idea as it represents the fulfillment of the dream of cost-efficient, non-petroleum plastic production. The huge advantage of PLA as a biodegradable packaging is its adaptability and the way that it normally decompose when exposed to the environment.

Sugar Cane

Starch

Corn

Biodegradable Packaging in Shelf Stable Barrier Packaging

Shelf Stable barrier packaging is designed to protect the contents from the migration of moisture and oxygen, maintaining freshness, and extending shelf life. The original barrier package was the tin can. In recent years, many lower cost alternatives have been developed.

Considerations when deciding on barrier packaging include:

Speed Of Use: Is the product consumed immediately, or very quickly, or does it sit on a shelf?

Preservation: Does the product contain preservatives or naturally have a long shelf due to its composition? Or is the product prone to decay?

Drying: Is the product susceptible to desiccation (drying out)?

Moisture Content: Do you need extended shelf life and does the product have a high moisture content?

Common examples of products that do not require barrier packaging are fresh fruits and vegetables, fresh bread and bakery items. These products can easily be packaged in Biodegrable packaging.

The hard part is developing biodegrable packaging for products that require barrier protection, and most consumer products require some barrier packaging to ensure they do not go stale and have an extended shelf life.

Biodegradable Packaging Certifications

Film data and compliance information was obtained from the film suppliers and given without any obligation on our part.

Eco-Friendly Material Options For Your Custom Packaging

At CarePac, we have two exciting new recycle-ready materials for making recyclable plastic bags. These materials can be used on both non-printed and custom printed orders. We’ll be with you every step of the way, to help you through the hurdles of developing your desired recyclable plastic bags to help your product come to life.

We divide our recyclable bags into two main categories based on their recycling type. Because of the way that standard plastic is non-biodegradable, it is important that as packaging as possible is recycled. It is fundamental to the global efforts to reducing plastic and solid waste in the environment.

5005 Recycle-Ready: Our “Code 4” material is a recycle-ready biax PE, it has a lower barrier than traditional lamination, but has nice clarity, and can be matte varnished.

5006 Recycle-Ready: “Code 5” cross laminate material with a PP base, it provides higher barrier than our code 4 material and has slightly higher strength. It is available as all matte or all gloss.

Recycling codes vary by jurisdiction; you will need to confirm recyclable with your jurisdiction.

Name | Eco-Friendly Style | Description | BioBased |

|---|---|---|---|

CareCompost-KP | Industrial Compostable | Paper exterior with PLA compostable barrier liner. | Yes |

CareCompost-KPS | Ambient Compostable | Paper exterior with PBS compostable barrier liner. | Yes |

CareCompost-KNMEPS | Ambient Compostable | Metalized Ambient compostable, FCN approved PBS material. | Yes |

CareCompost-NPS | Ambient Compostable | Clear ambient compostable material. | Yes |

CareCompost-KVP | Managed Compostable | Paper with Metalized PLA | No |

CareCompost-PVP | Managed Compostable | Metalized PLA | Varies |

Film data and compliance information was obtained from the film suppliers and given without any obligation on our part.

* MOQ varies based on size of the bag, please contact for details.

Eco-Friendly, Biodegradable, Recyclable and Compostable Bag FAQs

Whether you are new to custom printed packaging or a seasoned pro you may have a few questions about our products and process.

Q: Will compostable plastics break down?

Compostable bio-plastics will break down into soil unlike traditional plastics which last for hundreds of years. Most compostable plastics are intended to be composted in an industrial or commercial composting system, and may take much longer to break down under normal, at-home conditions. It’s also possible that the bag will take much long to break down with your product in it — depending on what your product is.

Q: Are compostable plastic bags freezer safe?

It depends, some materials can be frozen others can become brittle and crack when frozen.

Q: Are compostable plastic bags good for heated food?

Generally compostable bags are not a good choice for high heat application.

Q: Can you tell the difference between compostable plastic and regular plastic?

No, compostable plastic and regular plastic look and feel about the same.

Q: How are compostable plastics like PLA made?

Compostable plastics are generally made from a raw material such as corn, sugar cane and starch made from (PLA) polylactic acid and clear cellulose . Currently, the most common raw material uses in PLA is field corn, although other plant sources are being developed. Polylactic acid (PLA) is one of the primary alternatives to traditional oil-based plastics. Polylactic acid is highly popular as a plant-based polymer (a bio-plastic) because its general performance characteristics are similar to many non-compostable polymers and can be processed in similar ways. There are some distinct performance trade-offs that must be considered when using polylactic acid as a laminate element in flexible barrier packaging, but with continued technological advancements many of these limitations are being overcome. Below is a example of a bio-plastic bottle disintegrating under composting condition.

Q: What are compostable bags made from?

Polylactic Acid is principally made through two different processes —condensation and polymerization. The most common polymerization technique is known as ring-opening polymerization. This is a process that utilizes metal catalysts in combination with lactide to create the larger polylactic acid molecules. The condensation process is similar with the principal difference being the temperature during the procedure and the by-products (condensates) that are released because of the reaction. Here are some the reasons why biodegradable and compost barrier packaging made of PLA is a great choice for many applications.

Q: Can high barrier compostable plastic bags be produced?

The primary drawback of compostable materials like PLA is that it is a relatively low barrier material. PLA must be further processed or coated for use with liquids or products that require a higher MVTR (moisture vapor transition rate) barrier rating because uncoated PLA has a high-water vapor permeability. The primary solution to these limitations is to coat the PLA layer with additional elements. The most common MVTR boosters are coatings are: Aluminum Oxide, Silicon Oxide, and PVDC.

They are certified compostable by the Biodegradable Products Institute (BPI), petroleum-free and registered as USDA Bio-based Products. It is a cost-effective barrier that has been used for granola, candy, chips, cosmetics, jerky, pharmaceuticals, powders, and many other products.

Q: Can compostable plastic be used as a barrier film?

PLA can be processed into either a COEX or Biaxially oriented film (BOPLA). BOPLA is the most common form of film used for flexible packaging as a barrier film. PLA based compostable plastic bags can specifically replace PET, and biax PP film layers for many application. When PLA is laminated to a paper it can create a more durable packaging solution than when PLA is cross laminated to itself.

Q: What are biodegradable bags made from?

These bag are made from bio-plastics, which are plastics produced using renewable raw plant materials. Most of the materials we sell that are biodegradable are made of some combination of sugar cane, beets, and other starchy plants. Regular plastic is made with petroleum-based plastics and occasionally combined with other materials. With biodegradable plastic bags, you get a substance produced using renewable resources.

Q: Are compostable bags the same as biodegradable bags?

Compostable is a subset of of biodegradable and as far as packaging is concerned these are very similar terms. Home composting refers to packaging that can be composted (biodegrade) under ambient conditions, while the more general “OK compost” may refer to industrial composting conditions, (solid waste facilities)

Q: What’s the difference between bio-based plastics and biodegradable plastic?

“Bio-Based Plastics”, and “biodegradable plastic” are phrases that represent two different attributes, but the two terms, bio-based and biodegradable, are often used in conjunction with one another. When the terms are paired as modifiers with the term plastics, the phrase bio-based and biodegradable plastics denotes a composition deriving from mainly natural substances that break down over time, with the environment, the materials’ composition, and the time-frame all factoring in how quickly the break-down occurs.

Bio-based and biodegradable plastics are relatively new plastic materials to be used by the food packaging industries. As these newer bio-plastics degrade, they emit a very low amount of carbon, so they leave a very low carbon footprint. They are overall much more environmentally friendly than conventional plastics. Because these materials are much less harmful to the environment than fossil-based plastics, their use has been on the rise.

Small amounts of fossil-based plastics are still used in making some bio-based and biodegradable plastics, but the amount of petroleum plastic used in making bio-based and biodegradable plastics continues to be reduced with the invention of new polymers. As a result, bio based and biodegradable plastics leave significantly less plastic waste to damage the environment than do fossil-based plastics, and the amount of time required to decompose is reduced to three to six months instead of decades to hundreds of years or more.

Types of bio-based and biodegradable polymers are polylactic acid (PLA), biodegradable starch-based plastics, cellophane, biodegradable and bio-based polyesters, drop-in bio-based materials, polyethyline furanoate (PEF) and others. New bio-based and biodegradable polymers are under development including PBS.